About ITA

Since 1979, Infrared Thermographic Analysis (ITA) has been delivering a wide array of commercial and industrial thermography services to small-, medium- and large-sized companies across Canada. Our approach and years of experience are counted on to deliver cost effective preventative maintenance programs that minimize operational expenditures and allows maintenance scheduling rather than emergency repairs. ITA uses the industry's most advanced technology to quickly and accurately identify potential and existing maintenance problems that include:

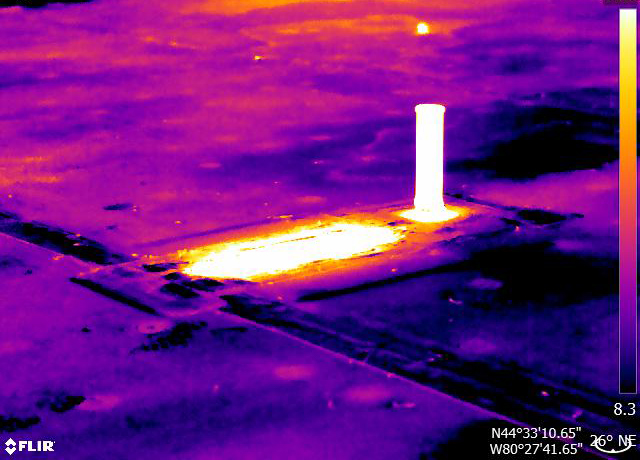

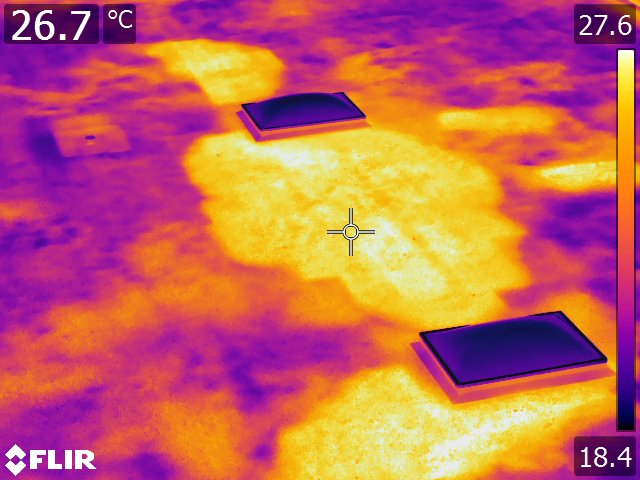

- Moisture Detection in Flat Roof Assemblies

- Building Envelope Evaluations

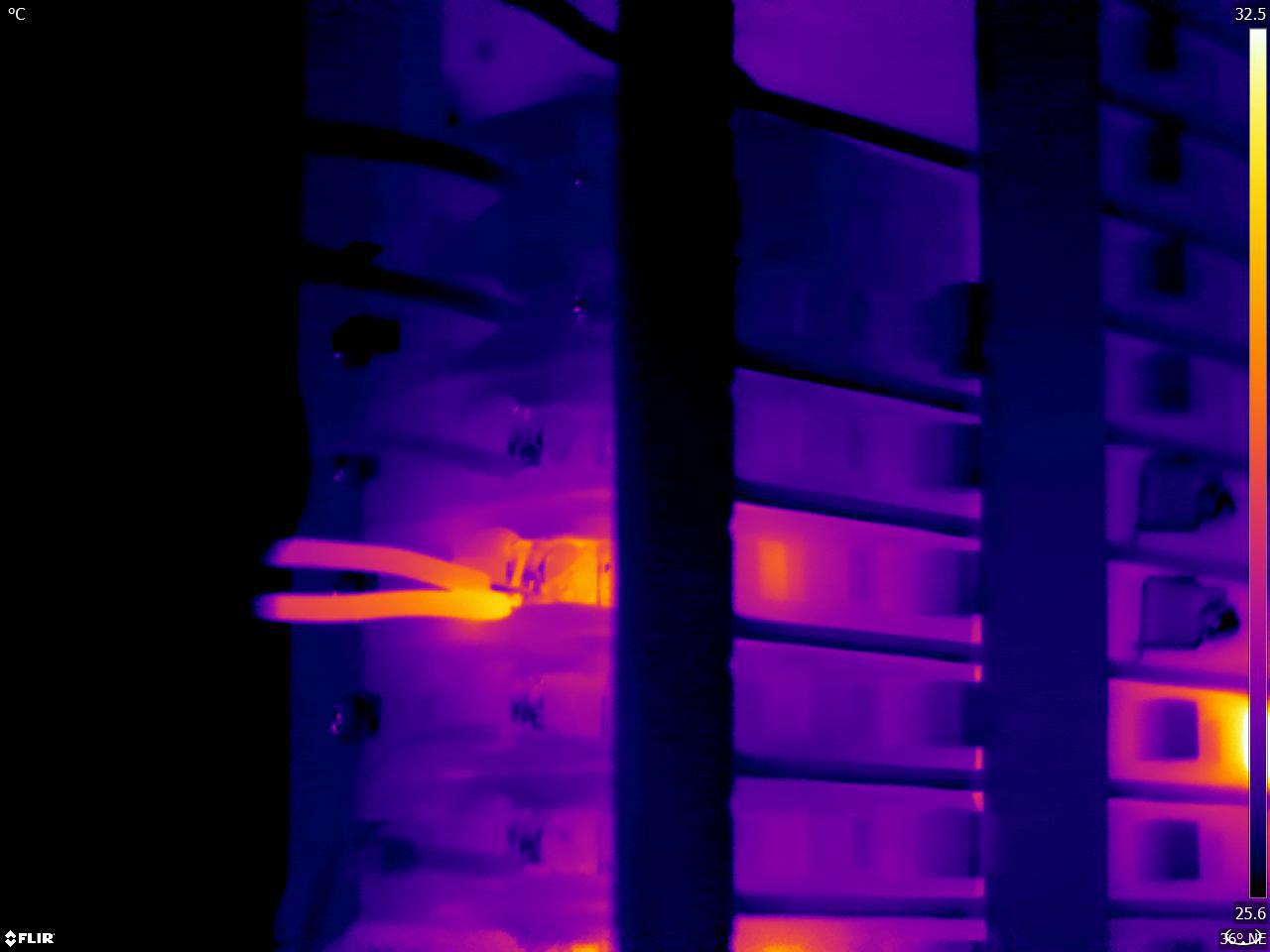

- Commercial Industrial Electrical/Mechanical Inspections

- Utility Overhead and Underground Faulty Electrical connections